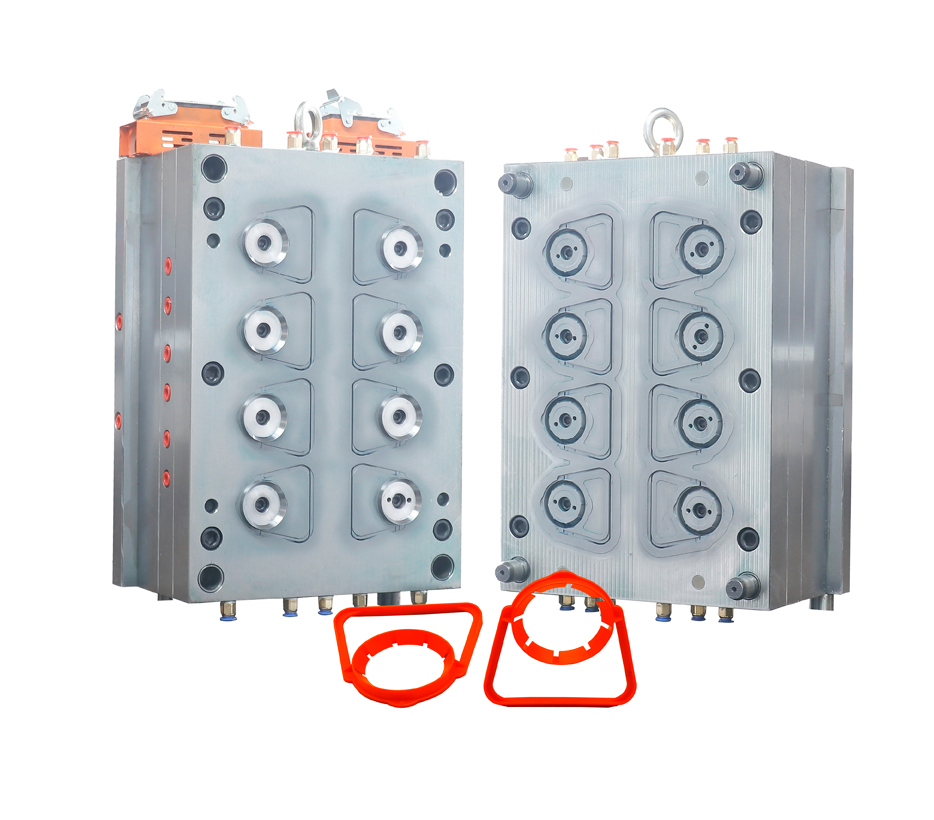

Customized Plastic Injection High Precision Bottle Cap Mould

Process of Cap Mould Manufacturing

1. Bottle Cap Design

2. Cap Mould Design

3. Cap Mould Manufacturing

4. Cap Mould Trial

5. Water Leakage Testing

6. Mould delivery

Why Shuanghao Mould for Plastic Cap Injection Molding?

We understand that the mould quality is the top concerns for all customers. Keeping that view in mind, our team focus on every steps from mould design, making and delivery.

Our factory always adopst high strength steel material to make bottle cap mold. The hardness of steel is generally more than HRC45. We use high-speed CNC machining center to process molds and carry out standardized operations, to ensure the accuracy of the parts of each bottle cap mold and achieve the interchangeability of each part.

During the mould manufacturing poried, we will report and update the mould status every wekk to customers. And we have a reputation for always meeting deadlines and dlivering mould on time.

Chinese cap mould maker which specialized in producing water cap mould and bottle cap mould. We can offer you different kinds of plastic cap mould solutions, eg, automatic unscrewing ejection cap solution, bi-injection system cap solution, complex flip top cap solution and irregular shape design cap solution.

-Adopt imported P20,2316 etc, steel.

-Hot runner is designed advanced and reasonably, each cavity heat controlled independently, temperature uniform.

-Each cavity and core have independent cooling system, shorten production cycle time.

HIGH SATISFACTION,PREFERENTIAL PRICES,QUALITY ASSURANCE.

Shuanghao Molds is a global brand established by a high-tech injection mold manufacturer. It has more than 25 years of R&D, manufacturing and sales experience in the field of plastic molds. Our R&D team has been continuously optimizing and improving plastic molds for many years. To provide customers and the market with high-quality, high-efficiency, high-speed plastic molds, to help customers realize the production of plastic products in the shortest time.

In order to ensure the cap dimension precision, dimension inspection is carried on after each mould plate tooling. For the flip top cap mould, we have successfully made 24 cavity cap mold with in-mold-closing system, to protect the flip top cap folding area efficiently.