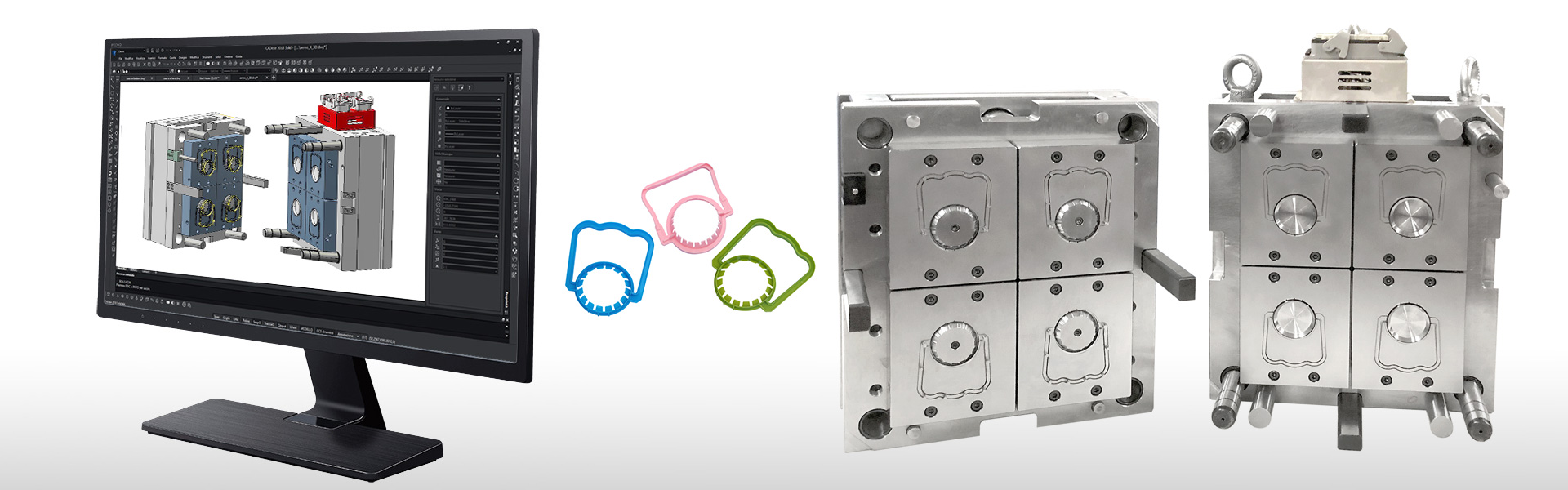

Plastic Handle mould

Handle mould is widely used for oil bottle and water bottle .The usually specification is from 1L to 20 L. There has some round type for catching the bottle part and the size type . Shuanghao mould can help customer design the new handle shape as per customer’s requirement. Shuanghao mould can help customer design the new handle shape as per customer’s requirement.

We take pleasure to introduce ourselves as the leading manufacturer and supplier of an excellent quality range of Plastic Handle Mould in the market. Offered mould is manufactured at our hi-tech manufacturing unit under the direction of highly accomplished professionals in compliance with the industry quality standards. To meet the set industry quality standard, offered Plastic Mould Handle is tested on various quality parameters by our experts. Further, these moulds are used for making various plastic handles .

- Description

| Product Name | Plastic handle mould |

| Core &Cavity Steel | 2316#steel, S136, H13, 718, SKD61, P20, S50C, 45#steel, 4Cr13, |

| 3Cr13, BeCu or based on customer's requirement. | |

| Mould base & Standard Component | DME,HASCO,MISUMI,LKM,Self-made etc. |

| Steel hardness: | HRC30-35 for base material. |

| HRC45-48 for core and cavity material. | |

| HRC60-62 for special parts material | |

| Plastic material | PP,,PE,HDPE etc. |

| Cavity Number | 1*4, 1*6, 1*8,1*12, 1*16, 1*24, |

| Injection System | Pin gate, Submarine gate, Valve gate etc |

| Ejector System | stripper plate, ejector sleeve, ejector pin |

| Cycle Time | Based on cap design |

| Tooling lead time | 30-60 Days |

| Mould life | At least 1.5million Shots |

| Handle Mold Feature |

| 1. Adopt imported steel P20, Germany 2316, S136 etc. |

| 2. Each cavity and core have independent cooling system, with independent parts for replacement |

| 3. Rational mold design to extend mold life and get high production efficiency. |

| 4. Mirror hand polishing and mold plates chroming to create added-value. |

| 5. Precision Machining to ensure high production efficiency & fine parting line effect. |

| 6. Skilled Language in communication and experienced in international standard. |

| 7. Hot runner system: China advanced brand or imported hot runner system brand. |

| Each cavity has independent temperature control and heater system. |

| Plastic handle mould | |

| 1.R&D | We support customer R&D. Make the files or improve the design if you needed. |

| 2.Quotation Making | Mould Quotation will be finished in 1 day according to information we get. |

| 3.Negotiation | The quality, price, material, delivery time, payment item, etc. |

| 4.Mould Design | 1-2days for product 3D/2D drawing design as per customer's design or our company's design. Then in further make the mould 2D/3D design. |

| 5.Mould | 1. confirm the proucts and the mold design |

| 2. Mould material prepare | |

| 3. Rough machining(heat treatment on mold base and pre-harden on mold) | |

| 4. CNC/ Vacuum Hardening on mold main spare parts | |

| 5. finishing machining( JDPAINT, DEM.etc) | |

| 6. Dimension inspection | |

| 7. Ejector& runner& cooling & other device process | |

| 8. Assemble mold | |

| 6.Mould Testing | When moulds are finished, we will test the mould and we will send samples for consumer reference. |

| 7. Sample confirmation | If the first sample is not satisfied by customer when it is come out. We modify the mould and until meet customer’s satisfaction. |

| 8.Delivery | Delivery goods by sea or by air, according to customer’s requirement. |

| Product Name | Plastic handle mould |

| Plastic Material | PPR,PP, PP+GF, PP+ TALC,PE,ABS,POM,PPH…etc. PC, PS, PMMA for Transparent. |

| Steel of Cavity & Core | Depends on Product, we help customer to choose the suitable material. Commonly used material as below: Buderus: 1.2311, 1.2738, 1.2344, 1.2316, BPM-HH, SUS-420…etc. Finkl: P20, HiP-20, H13…etc. Hitach: NAK80, DAC, FDAC, SKD61…etc. Assab: 618, 718, STAVAX…etc. |

| Steel of Mold Base | Depends on Product, we help customer to choose the suitable material.Commonly used material is S50C. |

| No. of Cavity | Customized |

| Hardness of Cavity & Core | Pre-Hardness Steel: HRC 30 ~ 32 ± 1° Heat Treatment Steel: HRC 50~52± 1° |

| Core pulling or Ejection system | Depends on the Product. Commonly used : Motor, oil cylinder, stripping plate, angel pin, ejector pin…etc |

| Mould Accessories | Compatible to DME/HASCO Standard. |

| Cooling System | In Core: Baffle or By pass cooling In Cavity Plate: Chain drilling type cooling |

| Surface Finish | Depends on the product. Commonly used: Texture Hatching, EDM Hatching, Polishing, Diamond Polishing…etc. |

| Mold Life | Depends on the steel hardness and the plastic material. Commonly used: 300,000 ~ 500,000 shots or 1 year under normal use procedure for Pre-Hardness material. 1,000,000 shots or 1 year under normal use procedure for Heat Treatment material. |

| Runner | 1. Cold Runner. 2. Hot Runner. |

| Delivery time | Depends on the product size and complication. For First trial: 45 ~ 80 days after mold drawings approved. |

| Packing | Standard Wooden Case |

| Machine Center | CNC milling machine, CNC Lathing machine, EDM, NC milling & lathing machine and so on. |

| R & D | We offer customers the drawings for products and mold design. Also we provide extra service such as: Reversing Engineering Drawing, Optical Design, Photometric Design… etc. We can work with 2D/3D drawings or with provided samples. |

| Production | We can also provide Pilot Run production and molding production. |