Manufacturing of Shampoo Bottle Cap Molds: Precision Engineering for Packaging Excellence

Introduction to Shampoo Cap Mold Manufacturing

Shampoo bottle cap molds are critical components in the cosmetics and personal care packaging industry. These molds must ensure high precision, durability, and smooth functionality for dispensing liquids while meeting FDA, ISO, and cosmetic-grade safety standards.

Key Stages in Shampoo Cap Mold Production

1. Design & Engineering

3D CAD Modeling – Advanced software (SolidWorks, AutoCAD) ensures precise dimensions for snap-fit, flip-top, or pump caps.

Flow Simulation – Optimizes plastic injection to prevent defects like warping or sink marks.

Material Selection – High-grade P20, H13 steel, or aluminum for corrosion resistance and longevity.

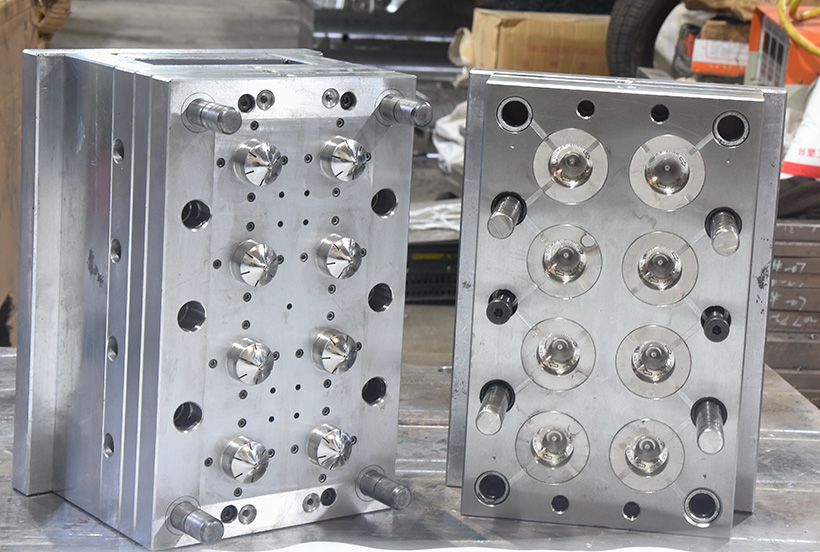

2. CNC Machining & EDM

5-Axis CNC Milling – Achieves tight tolerances (±0.005mm) for complex geometries.

Electrical Discharge Machining (EDM) – Creates fine details (threads, logos) with ultra-smooth finishes.

Hardening & Polishing – Extends mold lifespan (500,000+ cycles) with mirror-grade surfaces.

3. Injection Molding Process

High-Speed Molding Machines – Produces 5,000–50,000 caps/day with cycle times of 8–15 seconds.

Multi-Cavity Molds – 16–128 cavities maximize efficiency for bulk production.

Automated Ejection – Robotics ensure defect-free cap removal.

4. Quality Control & Testing

Vision Inspection Systems – Detect micro-cracks, flash, or misalignment.

Torque & Leak Testing – Ensures proper sealing and functionality.

Drop & Pressure Tests – Validates durability under real-world conditions.

5. Customization & Finishing

Engraving & Branding – Laser etching for logos, batch numbers, or QR codes.

Anti-Counterfeit Features – Tamper-evident designs for premium brands.

Eco-Friendly Options – Recyclable PP or PET materials for sustainable packaging.

Why Choose Professional Shampoo Cap Mold Manufacturers?

✔ High Precision – Ensures perfect fit with shampoo bottles.

✔ Fast Production – Reduces lead time with multi-cavity molds.

✔ Cost-Effective – Long-lasting molds lower per-unit costs.

✔ Regulatory Compliance – Meets FDA, EU, and ISO 9001 standards.