Precision in Every Detail: A Closer Look at Our Bottle Cap Mold Trial Process

At our specialized bottle cap mold manufacturing facility, we believe that excellence is achieved through rigorous testing and attention to detail. We’re excited to share a behind-the-scenes glimpse into the trial phase of a custom bottle cap mold currently in progress for one of our valued clients.

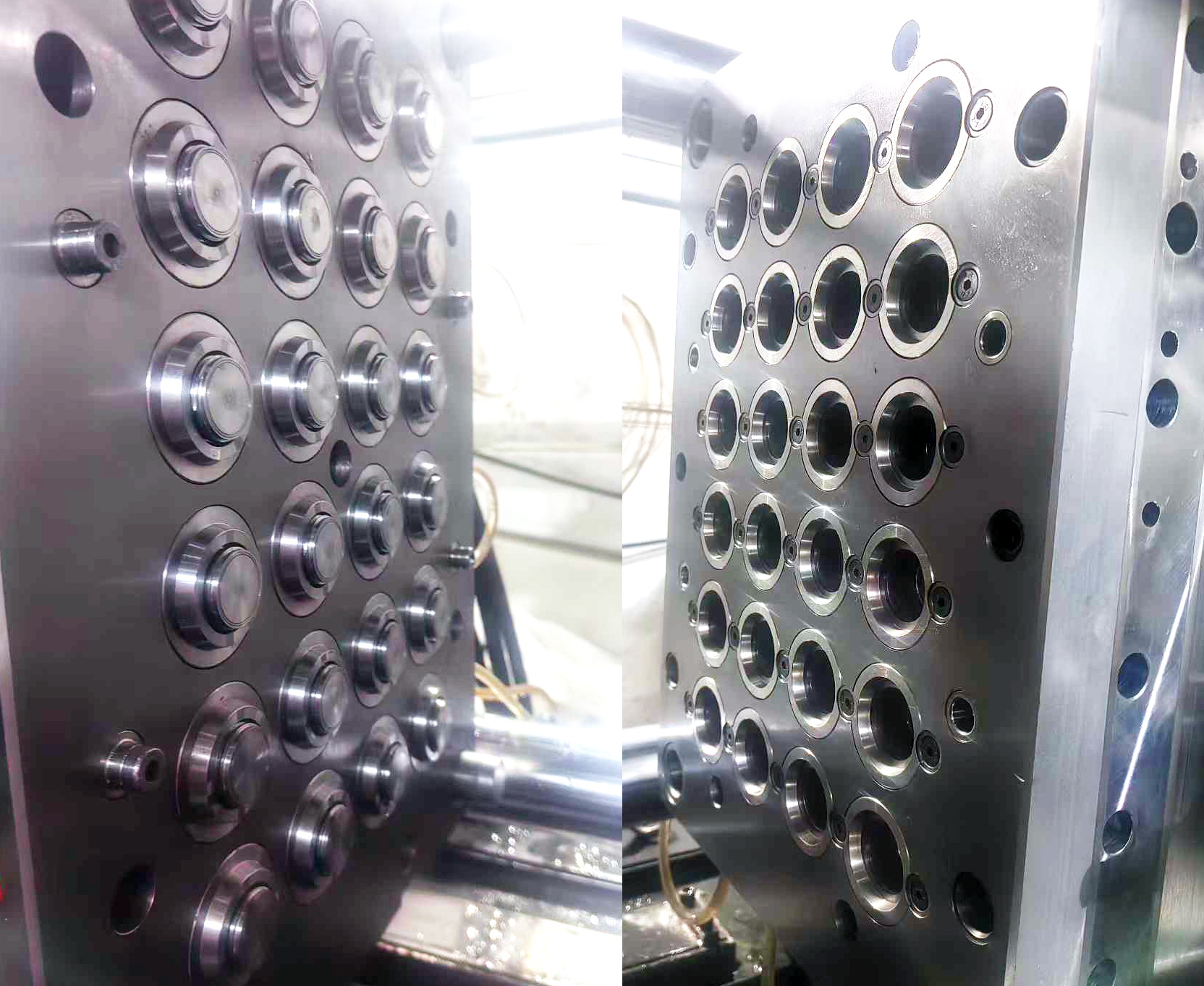

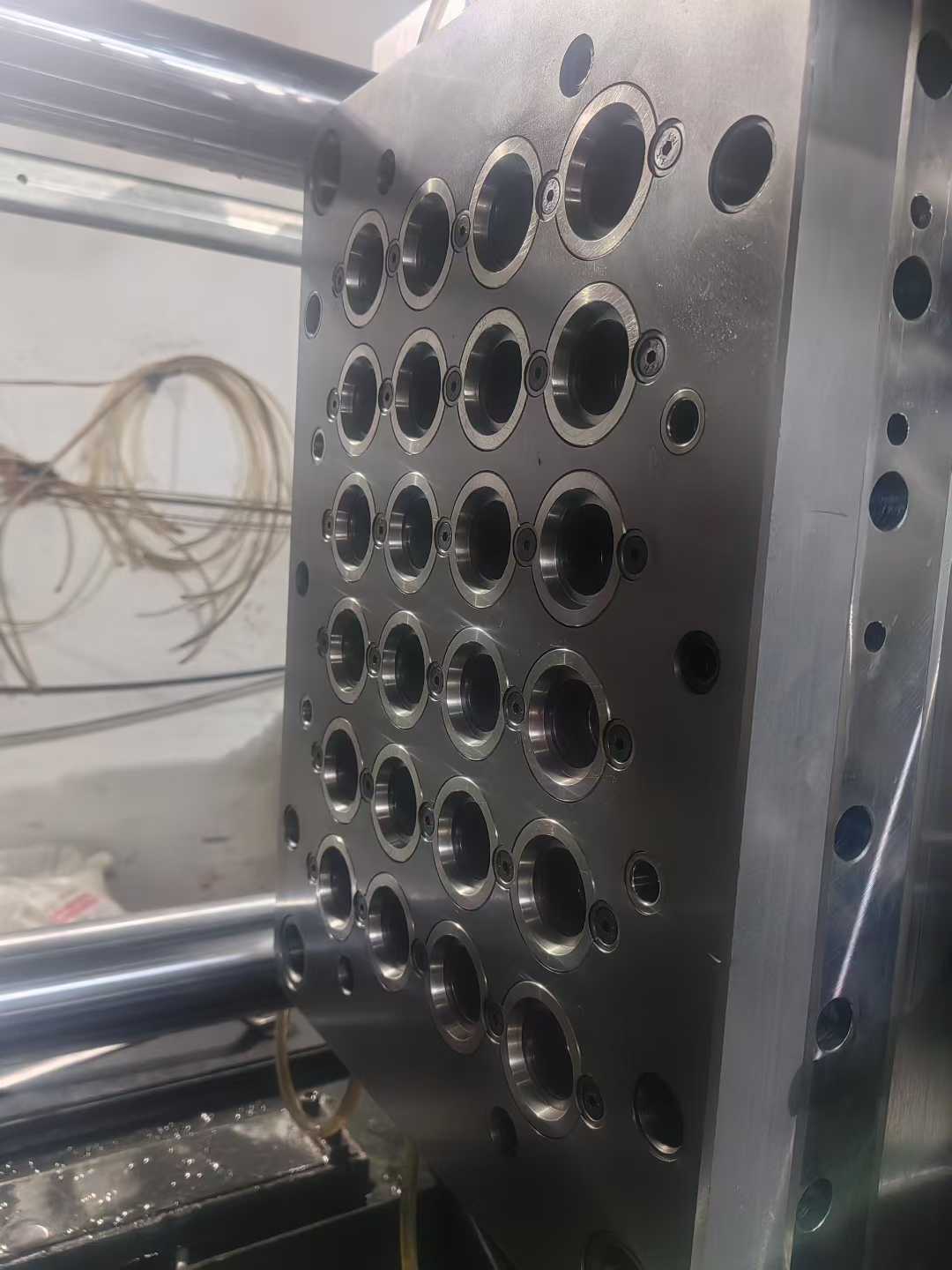

The images below capture key moments during the mold trial, showcasing the precision, craftsmanship, and advanced technology that define our production process. From the initial injection to the final cap output, each step is monitored closely to ensure optimal performance and quality.

[Insert photo 1: Mold setup in injection molding machine]

Caption: Our bottle cap mold securely installed in a high-precision injection molding machine, ready for trial.

[Insert photo 2: Close-up of mold cavity]

Caption: A detailed view of the polished mold cavity, designed for flawless cap formation and easy release.

[Insert photo 3: Freshly molded caps]

Caption: Sample caps produced during the trial, demonstrating consistency in shape, threads, and sealing surfaces.

[Insert photo 4: Quality inspection]

Caption: Technical team measuring cap dimensions and checking specifications against client requirements.

Why mold trials are critical:

Performance Validation: Ensures the mold operates smoothly under production conditions.

Quality Assurance: Confirms that every cap meets exact design and functional standards.

Problem Prevention: Allows early detection and adjustment of any potential issues before full-scale production.

We are proud to partner with clients worldwide, delivering durable, high-precision bottle cap molds that streamline their packaging production. This trial reflects our commitment to reliability, innovation, and customer satisfaction.

Stay tuned for more updates as we move toward final approval and mass production!