Bottle Cap Design and Manufacturing: A Guide to High-Quality Cap Molds

Introduction

Bottle cap design and manufacturing play a crucial role in the packaging industry, ensuring product safety, convenience, and brand appeal. Whether for mineral water bottles, beverage caps, or pharmaceutical packaging, a well-designed bottle cap mold is essential for mass production. This article explores bottle cap design principles, manufacturing processes, and the role of a professional cap mold factory in delivering high-quality solutions.

Key Factors in Bottle Cap Design

1. Material Selection

Most plastic bottle caps are made from:

Polyethylene (HDPE/LDPE) – Common for water and beverage caps.

Polypropylene (PP) – Used for hot-fill applications due to heat resistance.

PET – Lightweight and recyclable, ideal for eco-friendly packaging.

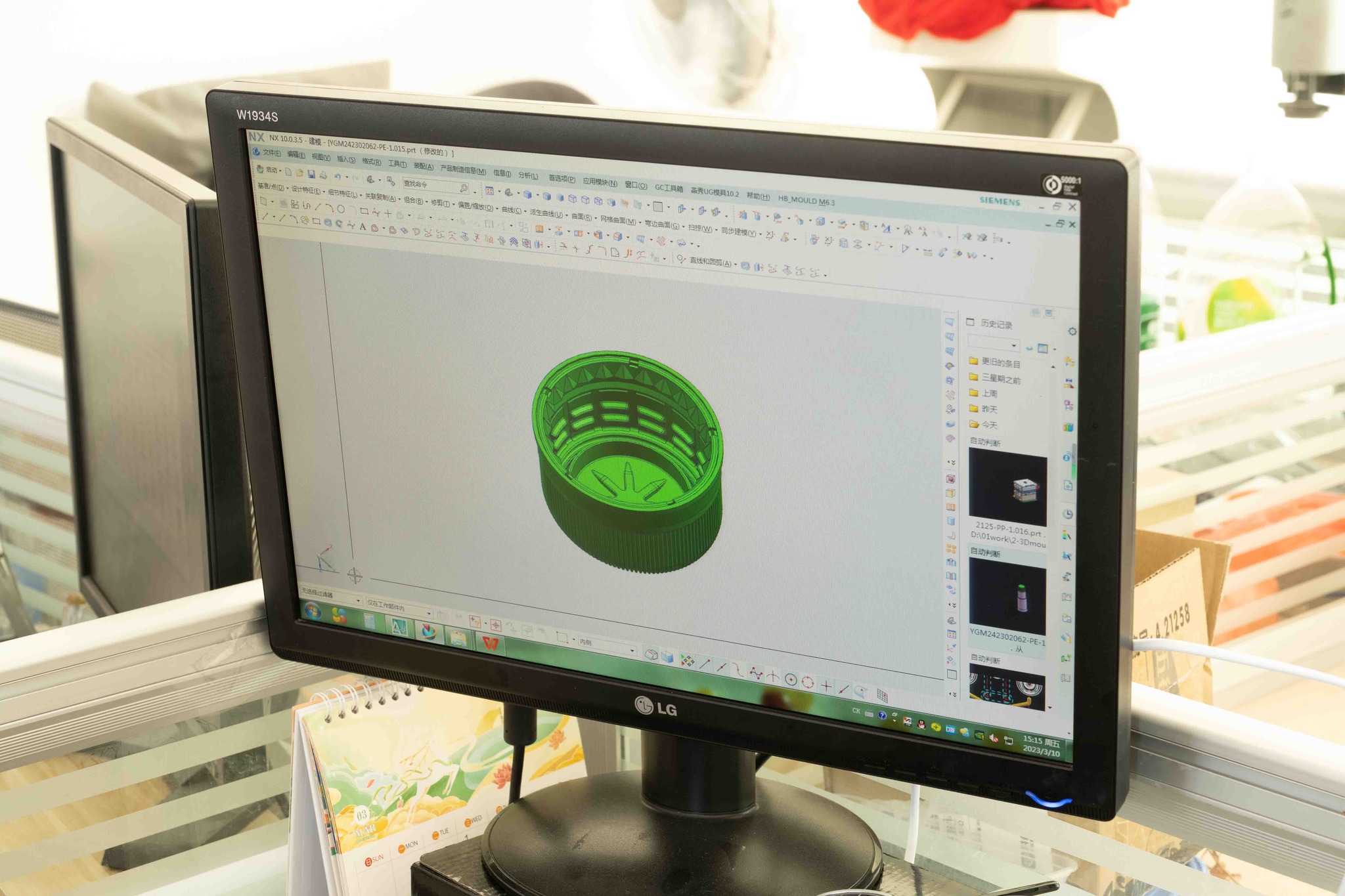

2. Functional Design Considerations

Leak-proof & Tamper-evident Features – Ensures product safety.

Thread Design – Must match the bottle neck for a secure seal.

Ergonomics – Easy-to-open caps improve user experience.

3. Aesthetic & Branding Elements

Custom Colors & Logos – Enhances brand recognition.

Textured or Embossed Surfaces – Improves grip and visual appeal.

Bottle Cap Manufacturing Process

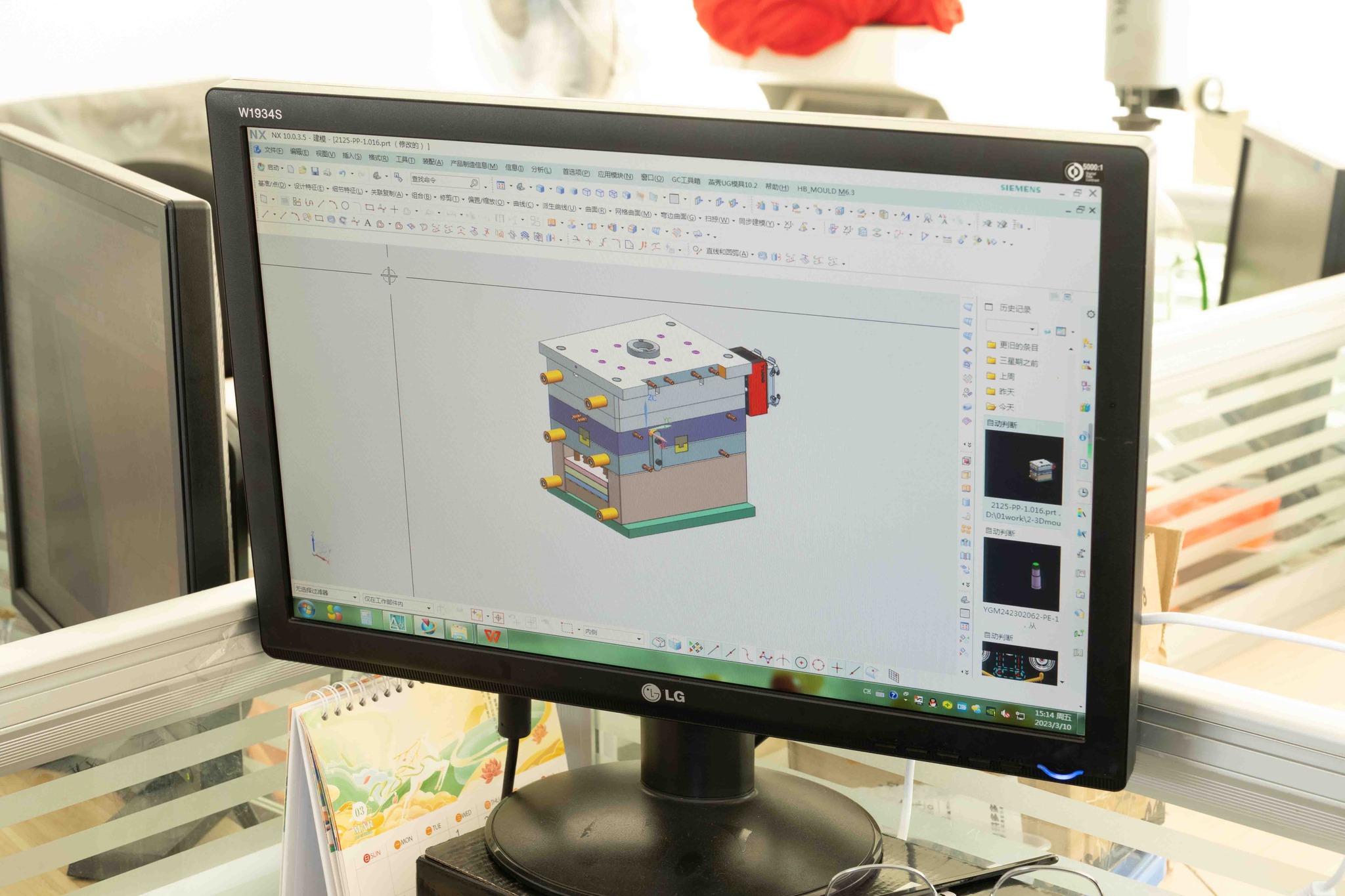

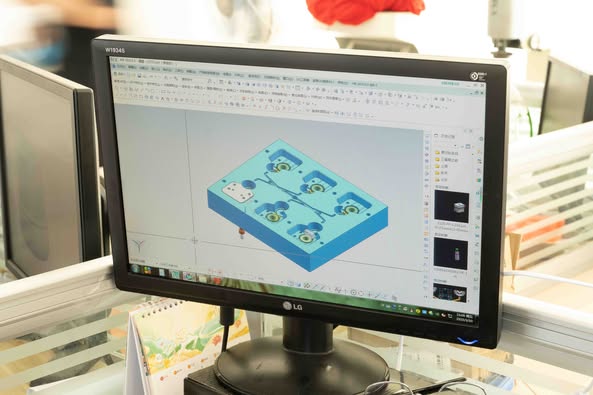

1. Mold Design & Engineering

A cap mold factory uses CAD/CAM software to design precision molds. Key steps include:

3D Modeling – Ensures accurate dimensions.

Flow Simulation – Optimizes plastic injection for defect-free caps.

Prototype Testing – Verifies functionality before mass production.

2. Injection Molding

High-speed molding machines produce thousands of caps per hour.

Automated Ejection Systems – Ensure consistent quality.

3. Quality Control

Dimensional Checks – Confirms thread accuracy.

Pressure & Leak Tests – Guarantees seal integrity.

Choosing the Right Cap Mold Factory

When selecting a bottle cap mold manufacturer, consider:

✔ Experience in Cap Mold Production – Look for factories specializing in plastic injection molds.

✔ Advanced CNC Machining – Ensures high-precision molds.

✔ Customization Options – Ability to design unique cap shapes and features.

✔ Quality Certifications – ISO 9001 compliance ensures reliability.

Conclusion

A well-designed bottle cap mold is critical for efficient, high-quality production. Partnering with an experienced cap mold factory ensures durability, functionality, and brand consistency. Whether for water bottles, beverages, or pharmaceuticals, investing in precision molds guarantees superior packaging performance.