The Precision Engineering Behind Flip Top Caps: A Comprehensive Guide to Mould Manufacturing

The flip top cap—a ubiquitous closure for cosmetics, personal care products, and pharmaceuticals—demands ultra-precision in mould manufacturing to ensure flawless functionality and aesthetics. This article details the advanced processes, technologies, and quality controls that transform raw materials into high-performance caps.

I. Design & Simulation: Laying the Foundation

1. 3D Modeling & Functional Decomposition

Flip

top caps feature complex mechanisms: hinged lids, snap-fit closures,

tamper-evident bands, and sealing surfaces. Designers use CAD software

to decompose these into:

Core/cavity for the cap body

Slide actions for undercuts (e.g., hinge recesses)

Lifter systems for internal threads

Ejection paths for delicate ribs46.

2. Virtual Validation via CAE/Moldflow

Computational tools simulate filling patterns, cooling efficiency, and structural integrity:

Shear analysis predicts flow-induced resin degradation in thin sections.

Warpage forecasting identifies sink marks near hinges.

Gate optimization ensures balanced filling for multi-cavity moulds, preempting dimensional inconsistencies18.

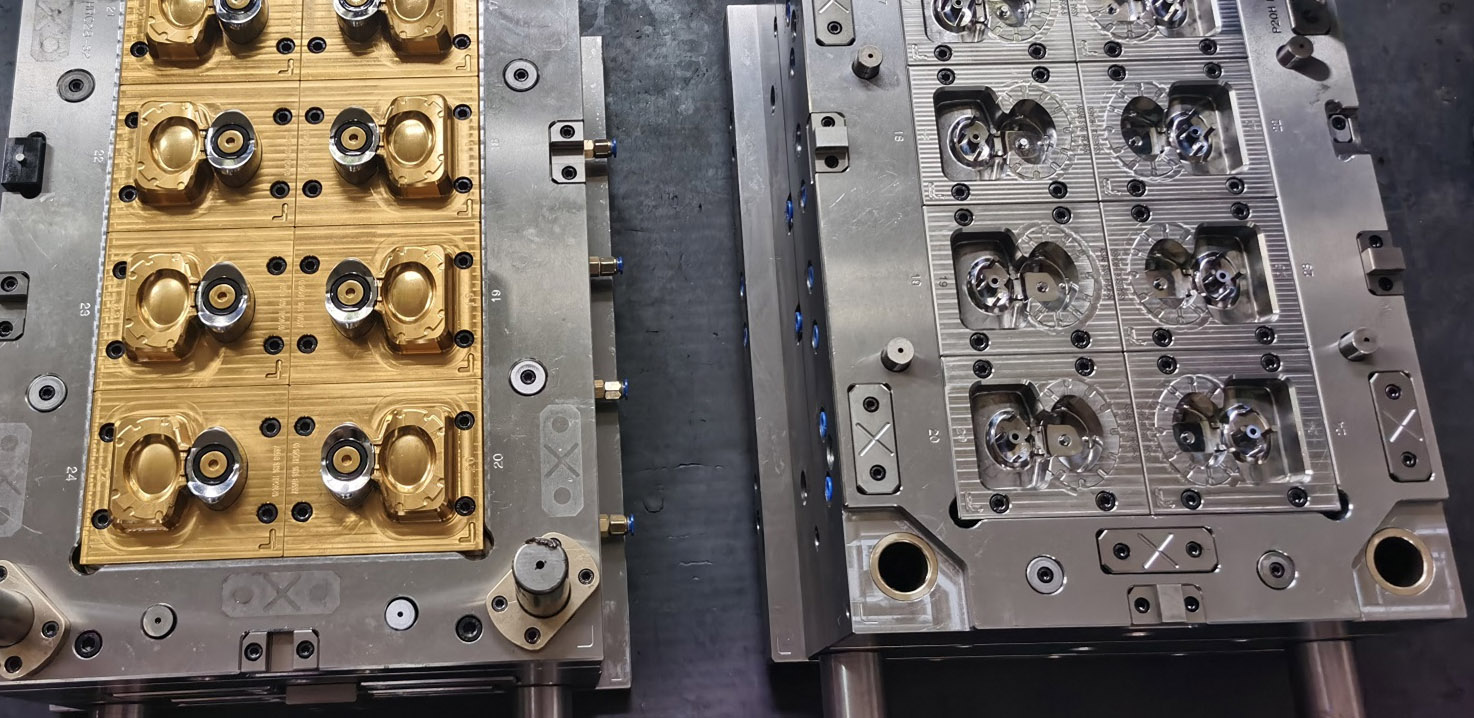

II. Core Manufacturing Technologies

1. Hot Runner Systems with Back-Gating

Critical for blemish-free surfaces:

Valve-gated nozzles inject resin into non-visible areas (e.g., cap interiors), eliminating gate vestiges.

Thermal management maintains resin viscosity, reducing flow lines and short shots6.

SEO Keywords: Hot Runner Systems, Gate Optimization, Injection Molding

2. Multi-Cavity Balancing with MeltFlipper™

Conventional geometrically balanced runners still cause 10–15% fill variation due to shear-induced temperature gradients. MeltFlipper™ resolves this by:

Rotating melt streams at junctions

Creating symmetric viscosity/temperature profiles

Achieving >99% cavity-to-cavity consistency8.

3. Advanced Ejection & Side-Actions

Slider-on-slider mechanisms form complex undercuts (e.g., latch features) without sticking.

Spring-loaded pins release caps from deep cores gently, minimizing deformation.

Hydraulic cylinders synchronize core pulls for high-aspect-ratio features4.

III. Mould Manufacturing Workflow

| Stage | Key Processes | Precision Metrics |

|---|---|---|

| Material Prep | Selecting tool steels (e.g., H13 for cores, stainless for cavities) | Hardness: 48–52 HRC |

| Machining | CNC milling, EDM for contours; laser texturing for matte/grip surfaces | Tolerance: ±0.005 mm |

| Assembly | Integrating lifters, slides, cooling lines; verifying kinematic clearances | Parallelism: <0.01 mm variance |

| Validation | Trial runs with T0 samples; dimensional checks via CMM | Warpage: <0.1% of cap diameter |

IV. Critical Process Controls

1. Cooling Design for Cycle Time Reduction

Conformal channels follow cap geometry, enabling 30% faster cooling vs. straight drills.

Baffle/thermal pins extract heat from thick zones (e.g., hinge knuckles)4.

2. Surface Perfection Protocols

Vacuum venting at weld lines prevents gas traps.

High-gloss polishing (SPI A1) for cosmetic surfaces; textured finishes for grip.

3. In-Mold Sensing & Automation

Pressure sensors detect micro-variations in cavity fill.

Robots handle caps to prevent scratching post-ejection.

V. Innovations & Trends

Hybrid Moulds: Combining soft TPE seals with rigid PP caps in a single shot6.

AI-Driven Predictive Maintenance: Analyzing sensor data to preempt core wear or contamination.

Sustainable Materials: Validated processing for recycled resins and bio-polymers.

Conclusion

Flip top cap mould manufacturing blends cutting-edge technologies—back-gated hot runners, MeltFlipper™ balancing, and smart automation—to achieve millimeter-scale precision at production scales. As sustainability and miniaturization advance, mould engineers continue pushing the boundaries of micro-injection and multi-material solutions.