Precision Plastic Bottle Cap Molds | OEM Mold Manufacturer & Factory

Engineering Excellence in Every Cavity: Your Premier Bottle Cap Mold Partner

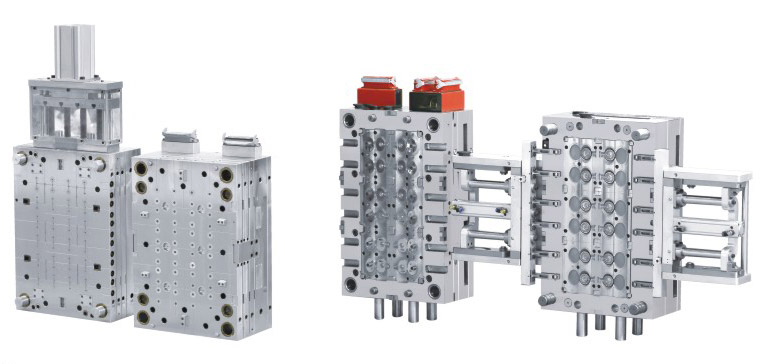

In the competitive packaging industry, the mold is the heart of production. It defines your cap's quality, precision, and ultimately, your brand's integrity. As a specialized plastic bottle cap mold factory and leading mold manufacturer in China, we design and build high-performance, durable injection molds that set the standard for reliability and efficiency.

Why Your Choice of Mold Manufacturer Matters

The quality of your bottle cap mold directly impacts your production output, unit cost, and product consistency. An inferior mold leads to downtime, flashing, sticking caps, and high maintenance costs. Our engineering expertise ensures your investment delivers maximum return through:

High-Cavitation Designs: Maximize output with multi-cavity molds (e.g., 16+ cavities) for high-volume production runs.

Superior Durability: Core and cavity blocks crafted from premium hardened steels (e.g., H13, S136) for exceptional wear resistance and long life.

Advanced Cooling Systems: Optimized cooling channel design for faster cycle times and increased production efficiency.

Automated Ejection: Designs that facilitate smooth part ejection and integrate seamlessly with automated assembly lines.

Our Cap Mold Expertise: Precision for Every Application

We are not just a mold maker; we are application specialists. Our team has extensive experience engineering molds for the entire spectrum of plastic cap designs:

Tamper-Proof Band Caps (Pilfer-Proof): Precise molds for creating secure, breakaway bands that guarantee product safety.

Flip-Top Caps & Closure Molds: Complex designs with integrated hinges for smooth, reliable operation.

Sports Caps (Push-Pull): Molds for creating leak-proof seals and user-friendly dispensing mechanisms.

Standard Screw Caps: High-efficiency molds for reliable, everyday closures.

Specialty Caps (e.g., EZ-Pour): Custom mold solutions for innovative designs with integrated funnels.

The Advantage of Partnering with Our Factory

Choosing us as your plastic mold manufacturer provides significant strategic and operational advantages:

End-to-End Service: From initial design and DFM (Design for Manufacturability) analysis to precision machining, hardening, testing, and after-sales support.

OEM & ODM Collaboration: We work as an extension of your team to develop custom injection molds that meet your exact specifications, whether you provide the design or need us to create it.

State-of-the-Art Technology: Our factory is equipped with advanced CNC machining centers, EDM (Electrical Discharge Machining), and high-speed milling technology for micron-level precision.

Rigorous Quality Control: Every mold undergoes stringent testing and sampling to ensure it produces perfect caps from the first production run.

Competitive Pricing: As a direct factory, we offer exceptional value without compromising on quality or materials.

Our Mold Manufacturing Process: Built on Precision

Consultation & Design Review: We analyze your cap design to optimize it for manufacturability and molding efficiency.

Precision Machining: Using CNC, EDM, and grinding machines to create mold components to exacting tolerances.

Heat Treatment & Surface Hardening: Applying processes like nitriding to enhance surface durability and extend mold life.

Assembly & Polishing: Meticulous assembly and polishing of cavities to achieve a flawless finish on your caps.

Sampling & Trial Run: We produce sample caps for your approval and perform rigorous testing before final delivery.

Ready to Optimize Your Production Line?

For bottle cap manufacturers, packaging companies, and large brands worldwide, we are the trusted partner for high-capacity, reliable injection molds.

Contact us today to discuss your project. Request a quotation and let our engineering team develop the perfect mold solution for your needs.