Your Professional Cap Mould Manufacturer

Shuanghao Mould Co., Ltd. is situated in Huangyan, a renowned "land of plastic mold" on the East China Sea coast. As a professional manufacturer, supplier, and exporter of bottle cap molds, we boast advanced scientific research technology, professional R&D and manufacturing capabilities, and a global sales network covering various regions around the world.

We can manufacture: Screw Cap Molds, Flip-Top Cap Molds, Sports Cap Molds, Snap-On Cap Molds, Tamper-Evident Cap Molds, Dispensing Cap Molds

What is a cap mould?

A cap mold, also known as a cap mould, is a specialized mold used in the manufacturing process of caps or closures for bottles, containers, or other packaging products. It is designed to create the specific shape, size, and features of the cap, such as the threads, tamper-evident bands, and sealing mechanisms.

Advantages Of Cap Molds

Long Service Life

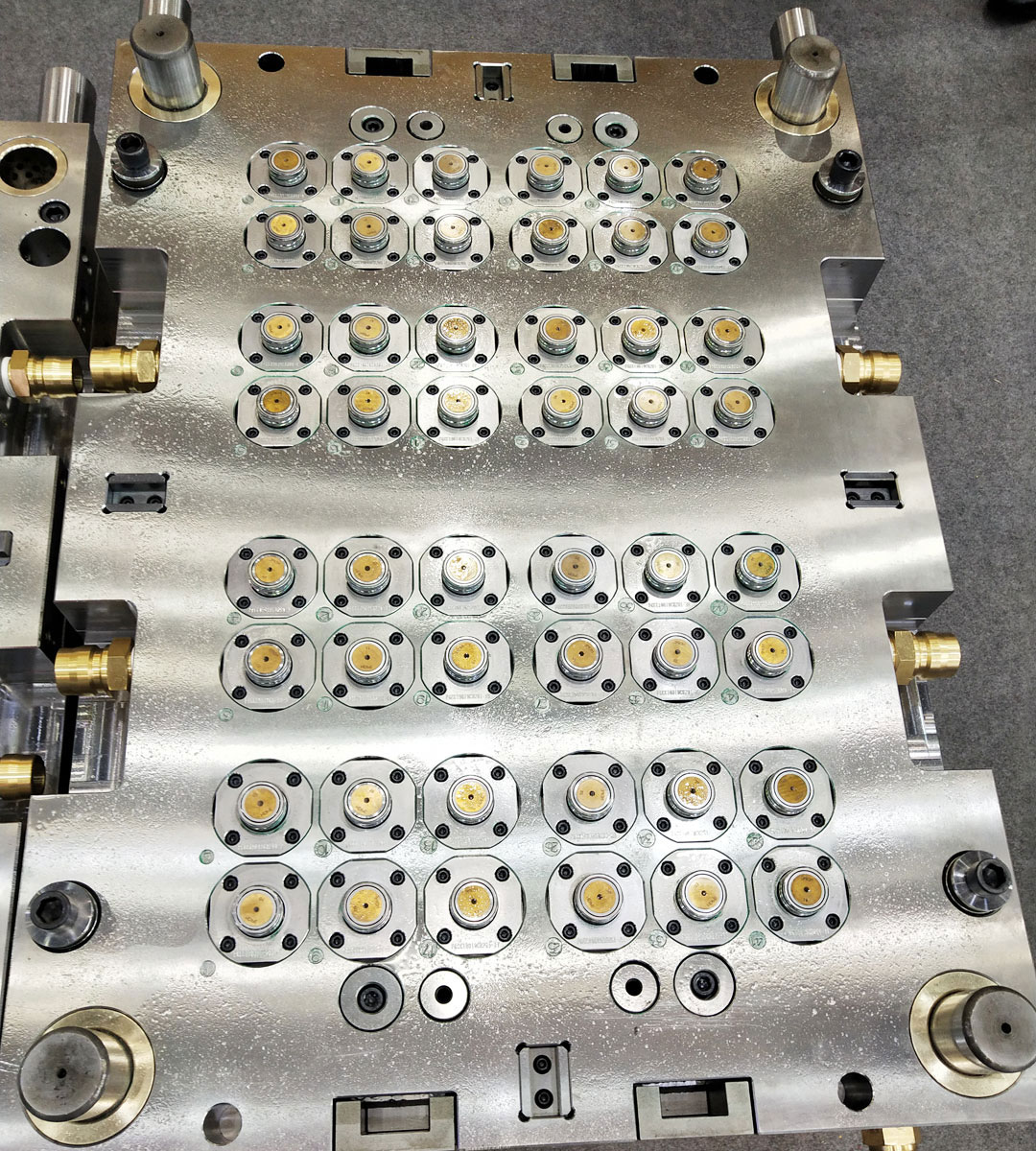

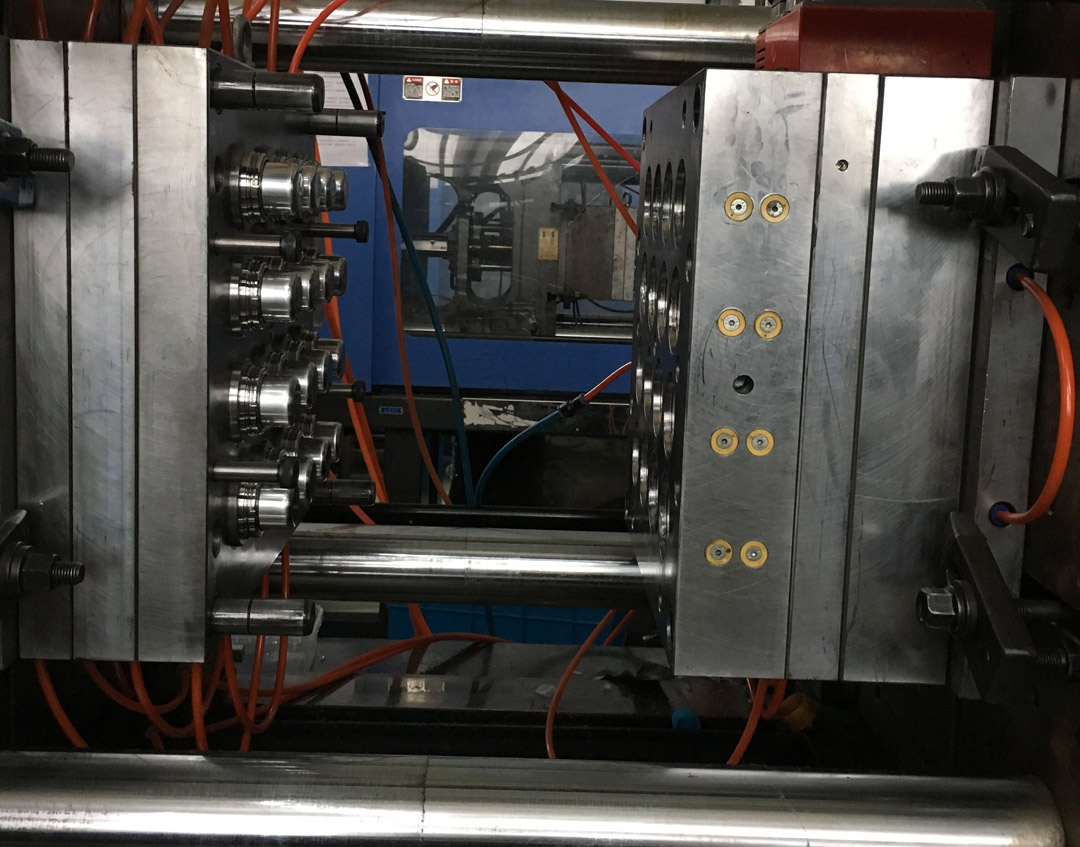

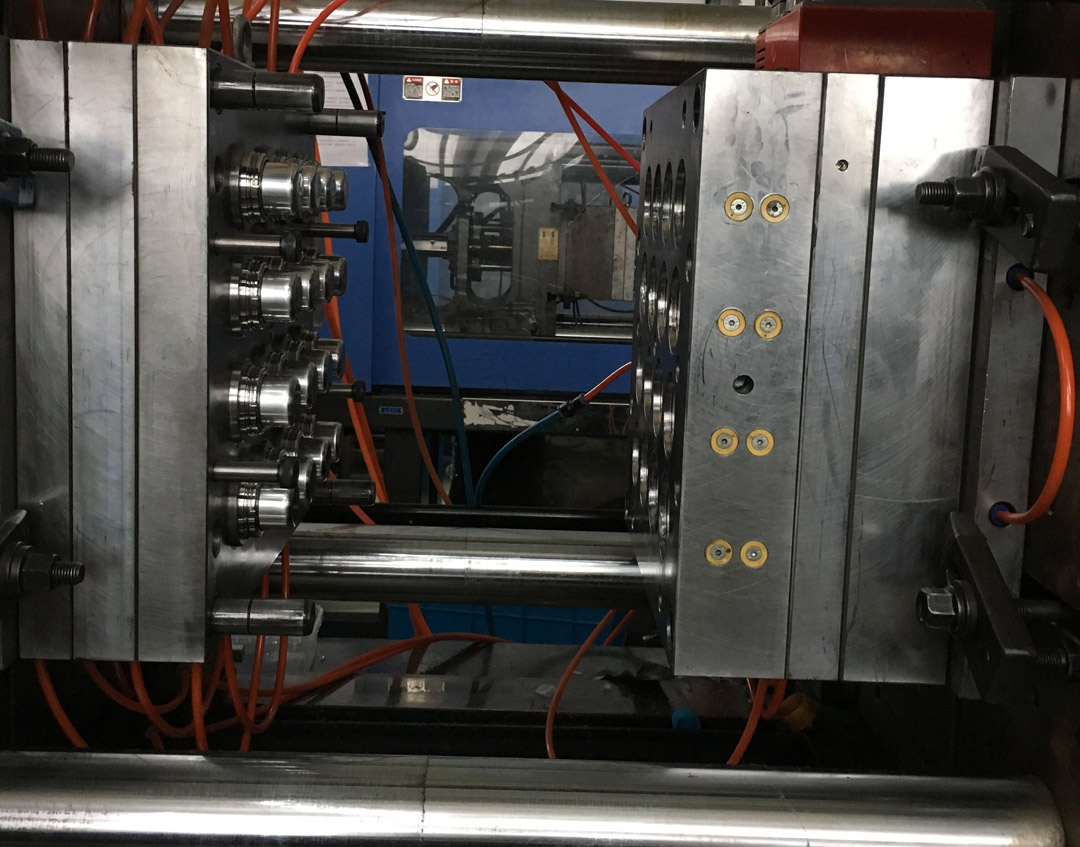

The mold core and cavity are made of Assarb S136 steel after heat treatment to ensure hardness and life.

Reduced Waste

A hot runner system with German heating elements accelerates plastic flow in the molten state, saves materials, and ensures product quality stability.

High Precision

Use advanced processing equipment to process molds with high precision. In addition, bridge-type three-coordinate measuring instruments and articulated arm measuring instruments are used to precisely control mold size.

Low Maintenance

Interchangeable inserts save material costs and are convenient for repairs and maintenance. We provide spare parts, such as core/cavity inserts and other replaceable mold parts, for quick replacement of damaged parts.

Cost-Effectiveness

Cap molds can be cost-effective in large-scale production as they enable efficient and rapid manufacturing processes. The molds can be used repeatedly, reducing the per-unit production cost.

Versatility

Cap molds can be used for various types of caps and closures, including screw caps, flip-top caps, sports caps, and more. This versatility allows manufacturers to produce a wide range of caps using the same mold.

Applications Of Cap Molds

1.Packaging Industry: Cap molds are extensively used in the packaging industry for producing caps and closures for bottles, jars, containers, and tubes. They play a crucial role in ensuring product safety, freshness, and convenience.

2.Food and Beverage Industry: Cap molds are used in the production of caps for food and beverage packaging, such as water bottles, soda bottles, juice containers, condiment bottles, and more. They help maintain product quality, prevent leakage, and provide tamper-evident features.

3.Pharmaceutical Industry: Cap molds are utilized in the manufacturing of caps for pharmaceutical packaging, including medicine bottles, pill bottles, and vials. They ensure proper sealing, tamper resistance, and protection of medications.

4.Cosmetics and Personal Care Industry: Cap molds are employed in the production of caps for cosmetics and personal care products, such as shampoo bottles, lotion bottles, cream jars, and perfume bottles. They contribute to product integrity, ease of use, and aesthetic appeal.

5.Chemical and Industrial Products: Cap molds find applications in the packaging of chemical products, lubricants, household cleaning agents, and other industrial products. They help prevent spills and contamination and ensure proper handling and storage.

6.Automotive and Engineering Industry: Cap molds are utilized in the production of caps for automotive components, machinery parts, and engineering products. They assist in protecting sensitive components from dust, moisture, and damage.

7.Medical and Laboratory Settings: Cap molds are used in the fabrication of caps for medical devices, laboratory equipment, and specimen containers. They aid in maintaining sterility, preventing cross-contamination, and ensuring sample integrity.

Materials Used In The Cap Mould

Plastic Drinking Water Bottle Handle Mould

Cap molds can be made from various materials, depending on the specific needs and requirements of the product and manufacturing process. Some of the common materials used in the fabrication of cap molds include:

Steel: Steel is a popular choice for cap molds due to its durability, strength, and resistance to wear and tear. It is suitable for high-volume production and produces highly precise and consistent results.

Aluminum: Aluminum is another popular material used in cap mold manufacturing. It is lightweight, easy to machine, and has excellent thermal conductivity, making it ideal for rapid cooling and fast cycle times.

Stainless Steel: Stainless steel is used for cap molds that require high corrosion resistance, such as those used in the packaging of food, beverages, and pharmaceuticals. It is also easy to clean and maintain.

Brass: Brass is used for producing cap molds that require high precision and accuracy. It is an excellent conductor of heat, making it suitable for molds that require rapid heating and cooling.

Copper: Copper is used for cap molds that require excellent heat transfer properties. It is also highly resistant to deformation, making it ideal for molds that require high pressure and force.

Plastic: Plastic cap molds are used for producing caps with intricate designs and shapes. They are cost-effective and easy to manufacture, but have a shorter lifespan compared to metallic molds.