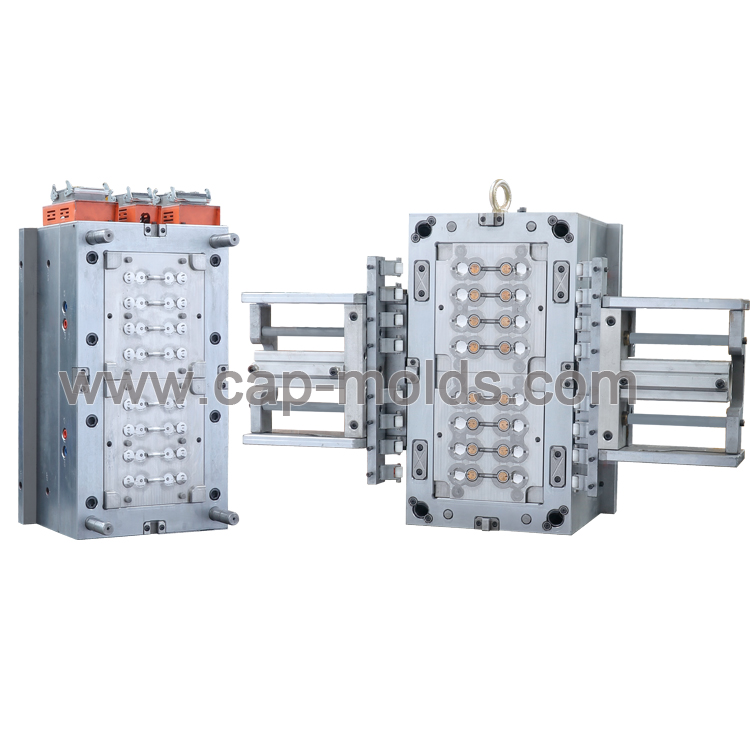

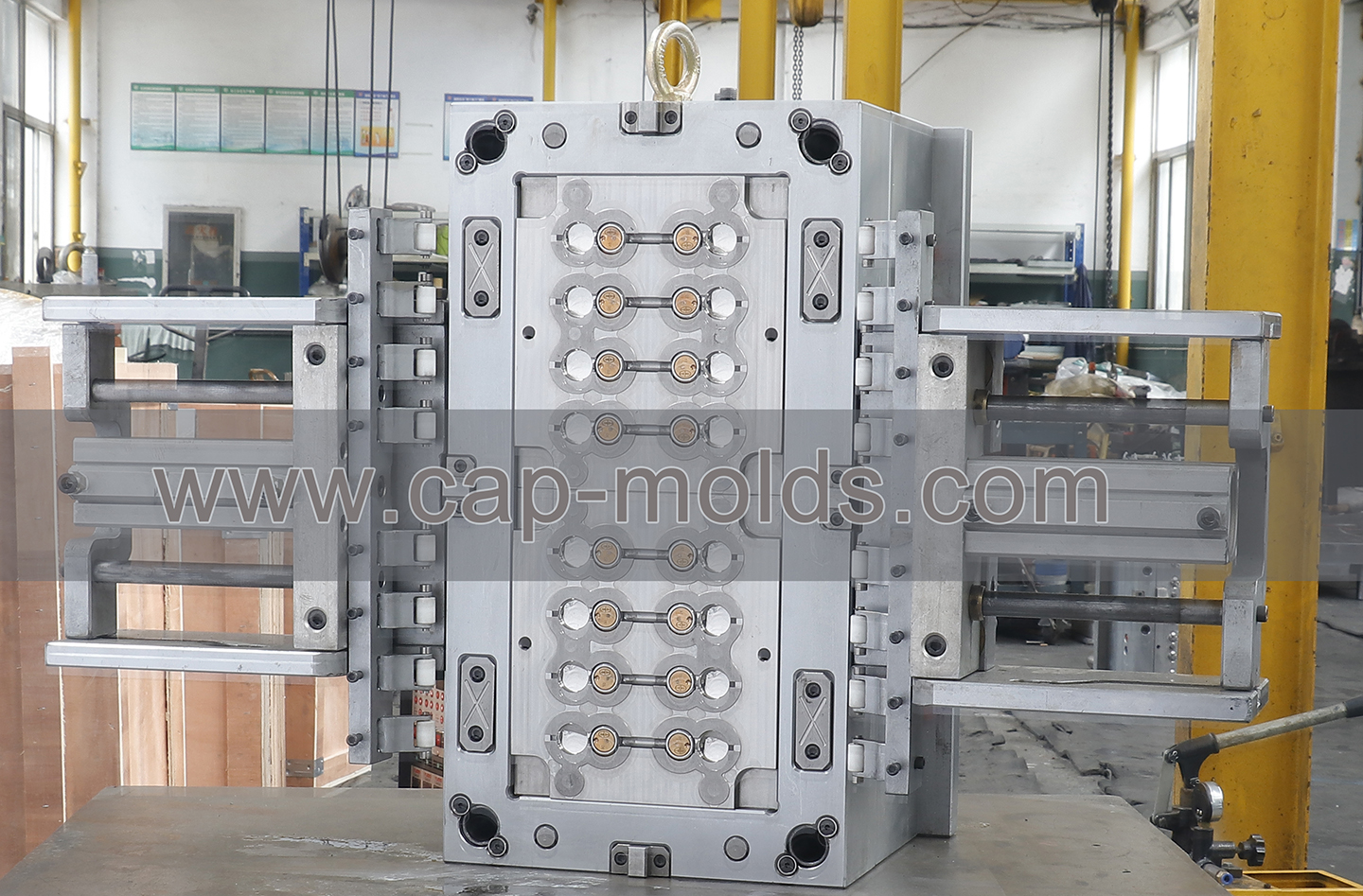

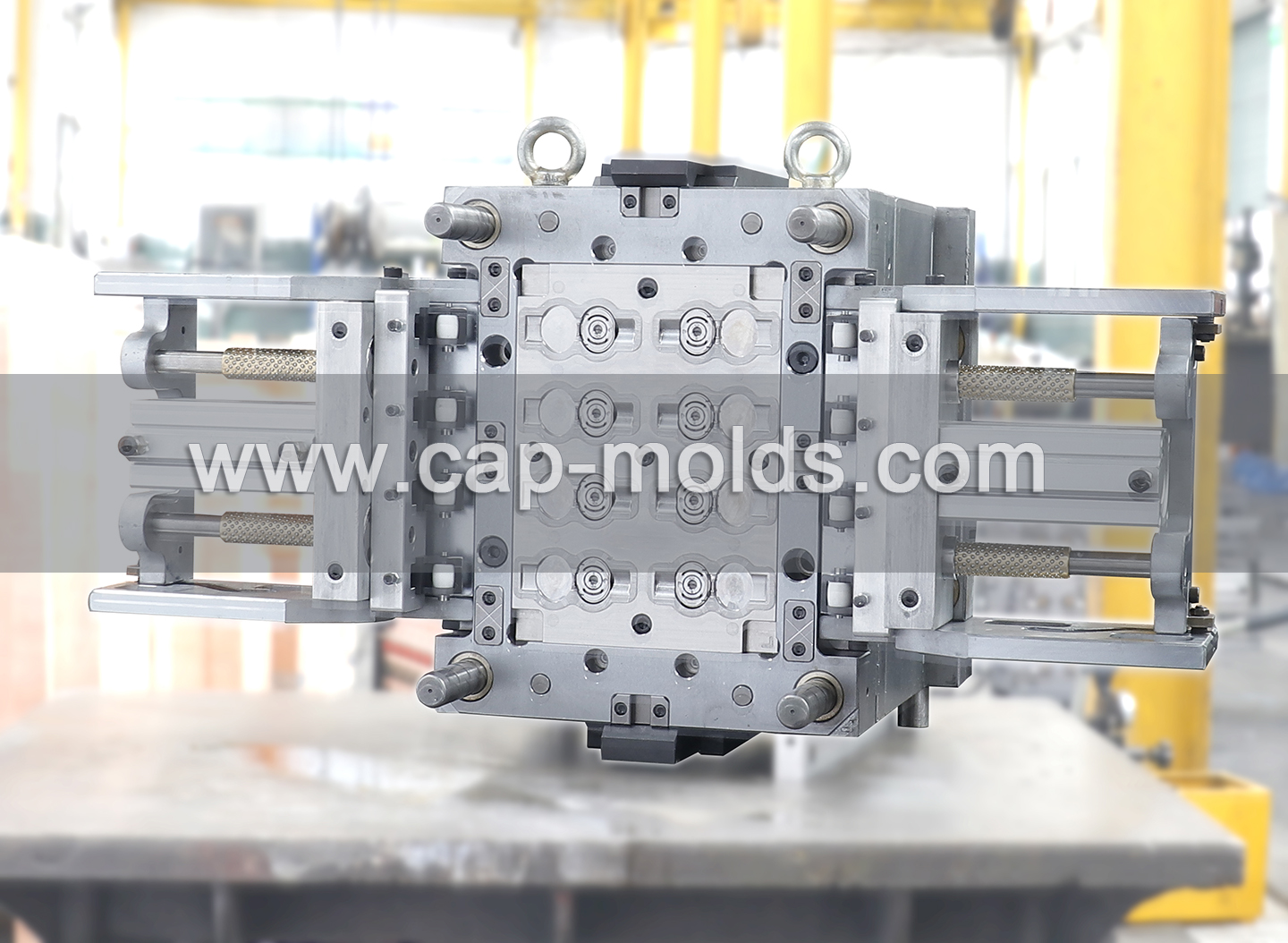

Plastic Flip Top Shampoo Cap Mould

professional plastic cap mould factory in China – especially on the flip top cap moulds design and manufacturing. We started to make flip top cap moulds since 2012. After more than 10 years experience, our flip top cap moulds quality are all on the high level.

Flip-top Cap & Closure Molds enable a hinge to be incorporated in the plastic part design. Parts are typically molded in the open position and may be ejected “open” or in the “closed” position. We make a variety of flip top closure molds with multi-point hinges, butterfly hinges and in-mold closing technologies for household, personal care, food, pharmaceutical, and beverage customers.plastic shampoo bottle Flip Top Cap mould,

- plastic cosmetic jar Flip Top Cap mould,

- plastic juice bottle Flip Top Cap mould,

- plastic milk jug Flip Top Cap mould,

- plastic cleaner container Flip Top Cap mould,

- plastic laundry detergent bottle Flip Top Cap mould,

- plastic salt and pepper shaker Flip Top Cap mould,

- plastic perfume Flip Top Cap mould,

- Description

PP Flip top cap mould steel

How to choose steel for flip top cap mould? Different plastic material, different mould life requirement, different performance on the plastic products finish and other special request on the mould principally use different grade mould steel. Most of flip top cap made by polypropylene. This plastic material is not so hard as PC, PMMA, Nylon, etc. Have widely choose on the mould steel.

Flip top caps widely used in the cosmetical packing, medicine packing, chemicals packing, etc. These are need huge quantity. So flip top cap mould need long life. In order to get long mould life, the mould steel need be improved on the hardness. As cosmetical packing, medicine packing, chemicals packing need their packing with high shinning and good looking appearance, in such flip top cap mould steel need with high shinning polish ability.

Custom Injection Plastic Flip Top Shampoo Bottle Cap Mould / Mold |

|

Item Name |

Custom Injection Plastic Flip Top Shampoo Bottle Cap Mould / Mold |

Manufacturing Method |

Plastic Injection Molding |

Runner System |

Cold Runner or Hot Runner (Valve Gate available) |

Parts Material |

Both hard and soft plastics, such as PP, ABS, HDPE, LDPE, PET, PVC, PA6, PA66, Nylon, PMMA, Acrylic, PVC, PU, TPU, PC, PS, HIPS, PC/ABS, POM, EVA, TPR, TPE, Delrin, PBT, etc. |

Parts Color |

1, Transparent / Clear 2, Any Color, Opaque (match as per pantone color number) |

Mould Material |

NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, 40Cr, 60#, 45# etc |

Mould Cavity |

8, or Single or Multi, as per your requirements |

Gate Type |

Sprue gate, Pin-point gate, Submarine gate, etc |

Design Software / Program |

UG, PROE, Solidworks, etc. |

Surface Treatment |

Polished (Glossy or common), Matte, Textured |

Mould Life |

10,000-1,000,000 shots |

Mold Building Lead Time |

15-60 days (average 30 days for medium size molds) |

Payment Terms |

T/T, Western Union, Paypal |

Mould Packaging |

Fumigation-free Plywood Wooden Case |

Transportation |

By Sea or by Air, as per your requirements |

Export Countries |

Worldwide (US, UK, Canada, Romania, Sweden, Italy, Russia, India, Iran, etc.) |

Capabilities |

1, Mold Building (common molds, hot runner molds, metal-to-plastic over molding / insert molding) 2, Parts Production 3, Logo Printing (Pad printing, Silk Screen Printing, Ultrasonic Welding, Painting, Plating, etc.) 4, Assembling (as per your detailed requirements) 5, Packing and Shipping |

Parts Production Lead Time |

3-20 days (as per different volume, average 3-7 days) |